I have had my cover offset using washers and longer hex bolts so that there’s around a 2mm gap between it and the chassis of the uConsole. It stopped the rear cover from pushing against the boards inside, but I wanted something a bit neater.

Having looked at gasket paper and messing with a 3D printed gasket solution, I came across some 2mm thick EVA foam sheets I had lying around from another craft project (available very cheaply online). So, as per the pics below, I used the rear cover as a template, cut out a gasket from the EVA, punched some holes and used M4x12mm hex bolts to secure the rear cover. But…!

I was back to 80 degree overheating, until I realised the bolts were the problem. The 12mm bolts kept the rear cover just slightly off the thermal pads inside and there was no heat transfer when the CPU temp went up.

I replaced the M4x12mm bolts with 10mm and tightened them until they compressed the EVA enough for the thermal pads to touch the case. It worked. The M2 heatsink on the rear cover immediately started to heat up and the CPU temp inside dropped back to between 58-62 degrees again.

Having stressed the CPU for around 10 minutes at 100%, everything remained stable and continued to run at no more than just over 60 degrees at the high end.

The gasket took less than 10 minutes to make, costs very little and works really well as a solution for me.

Gasket fitted, side view.

10mm Bolts next to the originals.

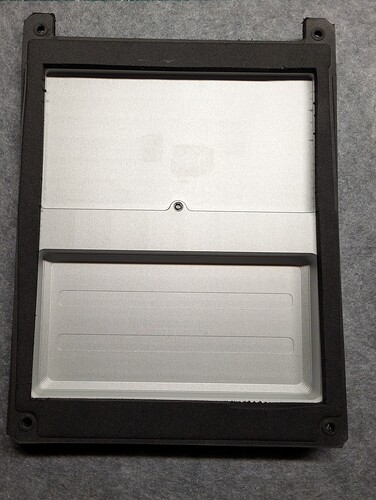

Gasket sat on the chassis.