standard thermal pad in uconsole is like ~4mm. thick boy!

if you won’t abuse CM5 or will underclock it – you won’t need riser board. but some people have throttling and riser board is a simplest way to achieve better conductivity (by using thinner thermal pad).

I’m using the stock thermal pad with my CM5 with a slight overclock and I don’t get thermal throttling. As long as there’s good contact the stock pad works fine.

Thank you very much for your sharing.

Unfortunately, following your description, I purchased the adapter and a 0.5mm thermal pad. After assembling them together and trying to install the back cover, I found that the back cover could not close tightly—there was a gap of about 0.5mm in the middle. I tried to reduce this gap by tightening the screws, and eventually managed to shrink it to about 0.2mm, I think.

However, after this, my uConsole would NO LONGER POWER ON.

After an hour of swapping and checking components, I confirmed that my CM5 was DAMAGED DUE TO THE PRESSURE.

I’m not sure if my case is just an isolated incident, but I want to remind everyone interested in doing this: if you notice a significant gap, PLEASE DO NOT TRY TO ELIMINATE IT BY FORCEFULLY TIGHTENING THE SCREWS.

This is very important feedback. Do you suggest that there was close to zero gap between the cm5 board and the cover even before using the thermal pad? I plan to do the same - riser board with cm5 board so will have to be careful. (for now waiting for my uconsole)

I have done this to 3 devices and had no issues. Yes i have a litte gap but i am okay with that i may got thermal paste soon which will close the gap.

How much space is between cm5 and cover when tightly closed? Can you please test maybe with paper sheets (before you put the thermal pad) ?

I sugest not to over tighten screws the gap is not too much but i will use a rhinner thermal pad or paste. I will take some pictures when i get a chance.

I don’t have the proper tools to measure it, but judging from the numbers and considering the flexibility of the CPI-RPI adapter itself, I think the gap on my uConsole might actually be less than zero.

Wow. So even with no thermal pad the cm5 touches the cover? So using the cm4 riser is maybe a bad idea?

At least in my case, the experience was really bad. It’s strange to me that others have reported being able to assemble everything smoothly.

Since I only have one set of uConsole, I can’t tell if every component is manufactured to exactly the same standard size—the uConsole mainboard, the adapter board, the CM5 (which is probably manufactured very precisely), and the back cover… I can only guess that there might be some production batch differences in the size of one of the parts.

Again, if you notice a gap, please don’t try to forcefully tighten the screws ![]()

I think thermal paste would be the better solution which should reduce the gap.

Just as another point of information. I simply swapped the CM4 for a CM5 - no riser and I did not even touch the rather thick original thermal pad. It was stuck to the bottom shell anyway and I checked that the CPU occupies about the same spot, so I gently pressed the bottom shell on the CM5 and screwed everything back together.

The pad was definitely thicker than the available space leading to some compression of it (just like with the CM4) Everything works as expected now. The bottom gets noticebly warm when I use the uConsole which means that heat is transferred. I have not made a load test, so I don’t know about throttling. But for normal use it is working perfectly.

Did the same, used the original thermal pad.

wouldn’t it be easier, to stick a copper / aluminium plate, about 1"/1" (25mm * 25mm) to the back of the case, so that it shrinks the distance, instead of rising the cm5 board?

I think I will try that, and report back.

How did it go?

Planning to do this as well..

It went well.

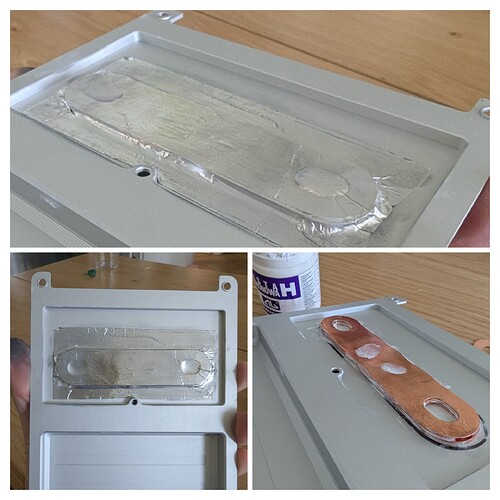

I didn’t have any copper plate for that thickness, but had a few thinner strips that I stacked.

So I added thermal paste, the first layer, thermal paste, second layer and so on. At the final layer, I taped everything down with industrial aluminum tape.

Good results. It definitely keeps the device cooler. Even with a long compile (40min ++), with CPU at 00%, it didn’t go above 58°C (136°F).

For those who prefer not to go the riser route and want to keep their back shell cooler and more comfortable to hold, I found this works well. Quick, simple, effective and relatively cheap.

2 layers of this thermal tape on the CM5 SOC:

Attach one of these heatsinks using 1” wide double sided thermal tape:

Drops temps on average ~10C. I was at ~60C under load and now I’m in 30s at idle and 41~50C under moderate loads. The shell back stays cooler and the build-in wire stand is about 1-2mm higher than the heatsink so their is a gap/airspace when placed on a flat surface with the stand is not in use.

Thank you for your reply, I’ll go the same route then.